Position: Home>PRODUCTS > Metal oxide arrester > Porcelain coat arrester

Product introduction

Surge arrester is also called overvoltage protector. It is connected in parallel with the protected electrical equipment. It can limit various overvoltage on electrical equipment, such as lightning overvoltage, operating overvoltage, etc., so as to protect the high voltage electrical from the damage of overvoltage.

Metaloxide varistor is used as the core component of surge arrester. The conductive mechanism of MOV is based on the non-linear volt-ampere characteristics of Schottky barrier model. The arrester is based on the principle of the non-linear volt-ampere characteristic of metal oxide varistor, which makes the arrester hold high resistance under the normal operating voltage of power system, which is equivalent to an insulator, and will not interfere with the normal operation of power system. When the overvoltage of power system endangers the safe operation of the system, the varistor triggers instantaneously and presents a low resistance. Forming a channel to release overvoltage energy, and clamp system voltage within the allowable range of the system to ensure the safe operation of the power system.

The arrester is porcelain-housed surge arrester. It has the advantages of high current impulse withstand capacity, large protection capacity and strong pollution resistance.

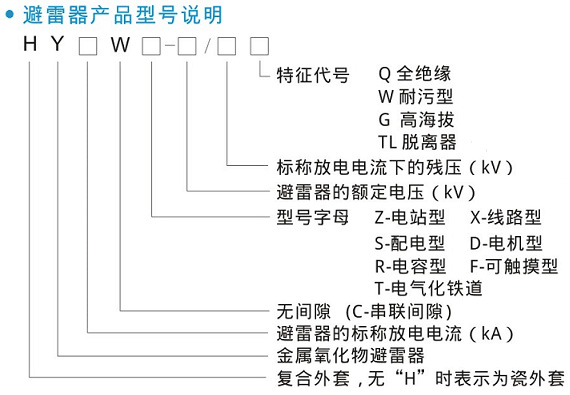

Type designation | Rated Voltage | Continuous operating voltage | Min. reference voltage at D.C. 1mA | Lightning impulse residual voltage 8/20 μs | 2ms rectangular current withstand | 4/10 μs high current impulse withstand |

kV | kV | kV | kV | A | kA | |

HY5WS-10/30 | 10 | 8 | 15 | 30 | 150 | 65 |

HY5WS-17/50 | 17 | 13.6 | 25 | 50 | 150 | 65 |

HY5WZ-10/27 | 10 | 8 | 14.4 | 27 | 150 | 65 |

HY5WZ-17/45 | 17 | 13.6 | 24 | 45 | 150 | 65 |

HY5WR-10/27 | 10 | 8 | 14.4 | 27 | 400 | 65 |

HY5WR-17/45 | 17 | 13.6 | 24 | 45 | 400 | 65 |

HY5WD-8/18.7 | 8 | 6.3 | 11.2 | 18.7 | 400 | 65 |

HY5WD-13.5/31 | 13.5 | 10.5 | 18.6 | 31 | 400 | 65 |

HY5WD-23/51 | 23 | 18 | 31.9 | 51 | 400 | 65 |

HY2.5WD-8/18.7 | 8 | 6.3 | 11.2 | 18.7 | 250 | 65 |

HY2.5WD-13.5/31 | 13.5 | 10.5 | 18.6 | 31 | 250 | 65 |

HY5WZ-51/134 | 51 | 40.8 | 75 | 134 | 400 | 65 |

HY10WZ-96/232 | 96 | 75 | 140 | 232 | 600 | 100 |

HY10WZ-100/260 | 100 | 78 | 145 | 260 | 600 | 100 |

HY10WZ-102/266 | 102 | 79.6 | 148 | 266 | 600 | 100 |

HY10WZ-108/281 | 108 | 84 | 157 | 281 | 600 | 100 |

HY10WZ-200/520 | 200 | 156 | 290 | 520 | 600 | 100 |

HY10WZ-204/532 | 204 | 159 | 296 | 532 | 600 | 100 |

HY10WZ-216/562 | 216 | 168.5 | 314 | 562 | 600 | 100 |

Y10WZ-300/727 | 300 | 228 | 425 | 727 | 1500 | 100 |

Y20WZ-444/1106 | 444 | 324 | 597 | 1106 | 2000 | 100 |

HY5WT-42/120 | 42 | 34 | 65 | 120 | 400 | 65 |

HY1.5W-31/85 | 31 | 24.8 | 52 | 85 | 400 | 65 |

HY1.5W-60/144 | 60 | 48 | 85 | 144 | 400 | 65 |

HY1.5W-72/186 | 72 | 58 | 103 | 186 | 400 | 65 |

HY1.5W-96/260 | 96 | 77 | 137 | 260 | 400 | 65 |

HY1.5W-144/320 | 144 | 116 | 205 | 320 | 400 | 65 |

HY1.5W-207/440 | 207 | 166 | 292 | 440 | 400 | 65 |

HY1.5W-0.28/1.3 | 0.28 | 0.24 | 0.6 | 1.3 | 100 | 45 |

HY1.5W-0.5/2.6 | 0.5 | 0.42 | 1.2 | 2.6 | 100 | 45 |

浙公網(wǎng)安備 33021102000712號

浙公網(wǎng)安備 33021102000712號